Cake box suppliers

Hello everyong , this is kent from sunshine packaging, I want to share material of commonly used packaging product, such as cake box , cake board , bread bag,bakery , In this article, we will first share various materials of cake boxes.

Cake boxes are a big category,which are also divided into paper boxes, plastic boxes.

Firstlt let us know raw material of paper box. Common cake boxes on the market include ivory paper cake boxes, corrugated cake boxes, and kraft paper cake boxes. These raw materials are very common in daily baking life.

Paper boxes

1.Ivory paper cake boxes:

Advantage :Original pulp paper, high-grade packaging paper, white on both sides, no sandwich in the middle, fine and shiny on the front, slightly rough on the back, good print resistance, folding resistance, good stiffness and hardness.

Thickness:200g ,230g, 250g, 300g, 350, 400g;

Different thicknesses correspond to different cake box sizes,if you need tomake 4inch box , you can use 200g Ivory paper , if you need to make 6inch box, you can use 230g Ivory paper , 250g Ivory paper is suitable for 8” and 10” box, 300g Ivory paper can suitable 10-12inch box; 350g Ivory paper is suitable 12-14inch box;400g Ivory paperis suitable 14-16inch box .

Ivory paper cake boxes

Kraft paper cake boxes

2.Kraft paper cake boxes:

Advantage :Kraft paper is characterized by high strength, strong tear resistance, brown or yellow, and low price. It is the first choice for most packaging materials.

Thanks to its low cost and recyclability, kraft paper is widely used in paper bag packaging, clothing packaging boxes, clothing packaging bags, shoe packaging boxes, small commodity packaging and even cement packaging bags, chemical packaging bags, envelope paper, glue Packaging paper, asphalt paper, cable protection paper, insulating paper, etc.

Thickness:200g ,230g, 250g, 300g, 350, 400g;

Because kraft paper is relatively soft, it is generally used to make small-sized cake boxes and paper cup boxes.

3.Corrugated cake boxes

Advantage:

1.Light weight, good structural performance. The corrugated structure inside is similar to the arched structure, which can play the role of anti-shock and shock absorption, and has good mechanical properties.

2. It has many good protection functions for packaged items. For example, moisture resistance, heat dissipation, easy handling, etc.

3. The transportation cost is low, and it is easy to realize the mechanization and automation of packaging and transportation.

4. The change of specifications and dimensions is easy to realize, and it can quickly adapt to the packaging of various items.

5. It is convenient for sealing and bundling, and it is easy to automate operations.

6. It can adapt to the decoration and printing of various types of cartons, and can solve the problems of product protection and promotion very well.

7. The waste box is easy to recycle and reuse, which meets the requirements of environmental protection.

Corrugated cake boxes is very strong box, It's usually used to scale up a little bit of a multi-layer cake. Such as 8” ,10”,12”,14” 16”,18”,20”.

Plastic boxes

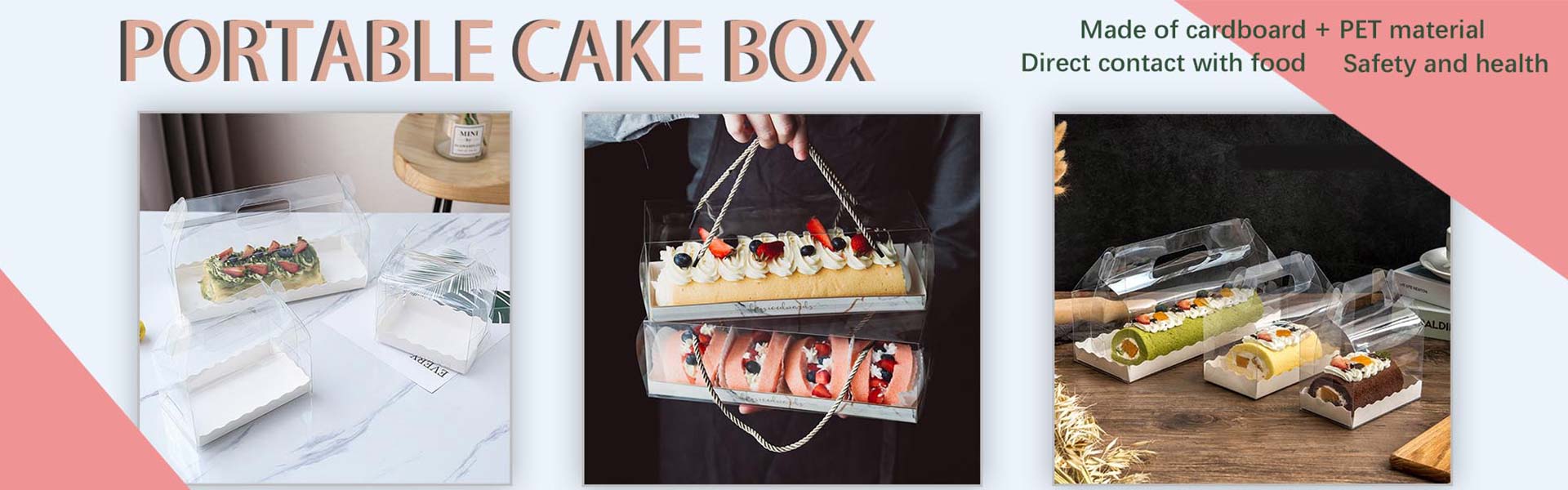

Plastic box is a relatively popular cake box, and the raw material used is an environmentally friendly PET material. There are other raw materials of plastic on the market, such as pvc, pp and other raw materials, but these are not environmentally friendly and recyclable materials, many countries prohibit the use of such raw materials.

1.PP plastic box

PP is a semi-crystalline thermoplastic. It has high impact resistance, strong and tough mechanical properties, and is resistant to various organic solvents and acid and alkali corrosion. It has a wide range of applications in the industry and is one of the common polymer materials.

The pp storage box is actually an ordinary storage box, generally made of ordinary PP material, not food-grade PP. PP is a resin with greater strength, density and transparency. Among all high-volume thermoplastic containers, PP has the lowest density, the highest melting point and relatively low cost, and can be made into flexible films or rigid containers for food packaging.

PP plastic box

PET plastic box

2. PET plastic box

Characteristics of PET materials: high transparency, high hardness, high biaxial tensile strength, good toughness, high temperature resistance, corrosion resistance, and good aging resistance. PET film materials generally use a smooth and transparent surface, and also have a frosted surface, but the sand surface is very fine, similar to a polished surface layer, and the polished surface is obtained on the PET surface, unlike PC.

The way is obtained by the sand surface of the roller during the mechanical calendering process, which also determines that its surface is not as obvious as the PC sand surface. The melting point of PET is much higher than that of PP, about 260 degrees Celsius, and is affected by the processing conditions, and will not shrink below 180 degrees Celsius. Injection-blown PET bottles are the fastest-growing plastic packaging in food packaging applications, and PET can also replace PVC materials for packaging of dry edible oils.

3. PVC plastic box

PVC is a polymer material that uses one chlorine atom to replace one hydrogen atom in polyethylene. The biggest feature of PVC is flame retardant, so it is widely used in fire protection applications. The packaging box made of it has the following characteristics:

①The structure of the transparent packaging box is reasonable, which provides a stable protective environment and exquisite appearance design for the product.

②In terms of materials, choose environmentally friendly and scratch-resistant high-transparency materials, which can not only ensure that the products will not be damaged during transportation and storage, but also meet the standards of processing, printing and environmental protection.

③Transparent packaging box, beautiful and high-grade design

Post time: Nov-04-2022