Established in 2013, Sunshine Bakery & Packaging is a well-known organization in the field, engaged in the manufacture and supply of various cake boxes, corrugated boxes and PVC tray products. The range of boxes offered is manufactured to meet the various requirements of customers in various industries and sectors.

Often used for packaging purposes, this range is considered to protect the material packaged within the compression-resistant range of the box, and we make sure to use qualitative raw materials obtained from the most valuable suppliers in the industry.

Widely used in transportation, marketing and merchandising, this series features high tensile strength, long service life, light weight and reusability. Manufactured under the supervision of hard-working team members, this collection is fully compliant with international quality standards and specifications, meeting customer needs and specifications in the most prominent way, producing high-quality products.

Our materials are always of the highest quality and ethically sourced, we only use industrial, EU-approved materials, ensuring the safety of your cakes and your customers at all times. Here are a few of our top selling products, including cake boards, cake boxes and cake stands.Mainly the following styles:

1. Sunshine Cake Drum, including wrapped edge and smooth edge. The colors that are often displayed are gold, silver and white. Now because black is more difficult to order, the other three colors are mainly recommended. Cake drum are generally 5 pieces in a bag of shrink bags, 25 pieces in a box, and this packaging method is machine operation.

A. For wrapped edge, 2 or more pieces of corrugated cardboard are compressed together to form a board. The main thickness is 10mm, 12mm, 15mm, and 18mm. Among them, 12mm is the most commonly used and our main recommendation.

After the corrugated cardboard body is finished, it is necessary to enclose the edges first, and then wrap it with a piece of 182g aluminum foil that is larger than the cardboard body (ps: the aluminum foil used for edging is soft and easy to fold and shape) .

However, the wrapping paper is relatively thin, so after sticking the wrapping paper, you will still see the corrugated cardboard lines, and there will be obvious wrinkles on the edge of the cake tray after wrapping the wrapping.

Next is the backing paper. Some customers may not seal a white book paper backing paper in order to save costs. As shown below:

B. The method of the corrugated main body is the same as the smooth edge , except that it will first wrap the edges tightly, and then cover the surface paper and the bottom paper.

For the surface paper, it is generally 275g aluminum foil paper, which is stronger than the edge wrapping aluminum foil paper. If it is thicker, it will be harder.

Generally speaking, you will not see the corrugated paper texture inside. At the end, stick a piece of white paper as a backing paper. As shown in the picture above:

The process of smooth edging will be a little more complicated than that of edging, and the price will be slightly more expensive, but it is more beautiful, which depends on the requirements of customers.

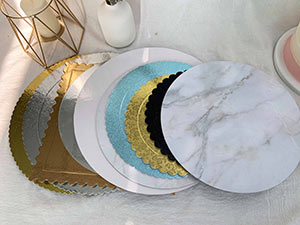

Cake base board: mainly double-grey wrapped edge and double-grey die-cut edge. For packaging, 25 pieces are in a shrink bag, and 100 pieces are in a box. This packaging method is also done by the machine.

A. Double-gray warpped edge: The double-gray cardboard is compressed together to reach the thickness you want, and then directly cut into the shape and size you want by machine, then wrapped with aluminum foil, and finally pasted with book paper. The main thicknesses are 2mm, 3mm, 4mm, 5mm.

B. Double gray die-cut edge: After the double gray cardboard is compressed to the thickness you want, it is directly cut into the shape and size you want with a machine, and then mounted on PET. It can be made with gears or without gears. The quotation is the same. In terms of shape, you can also make circle, square and heart shape. The quotation of circle and square is the same, and the quotation of heart is higher. There are 1.2.3.4.5mm thickness to choose from, but not too thick, because too thick the cutting machine cannot operate.

The commonly used thickness is 3, 4, 5, 6mm. When the MDF is purchased, it is already cut into the size and shape you need, and then the aluminum foil paper is used as the face paper, and the book paper is used as the bottom paper. Generally speaking, the cost of MDF is relatively high, but the load-bearing capacity is relatively good, and the weight to pick up is relatively heavy, so depending on the needs of customers, if you need to put some relatively large and heavy cakes, you can consider using MDF. The commonly used packaging method is also 5 for a shrink bag and 25 for a box. As shown below:

Cake Box

Divided into heaven and earth cover cake box and integrated box. The regular packaging is 25 PP bags, 50 pcs in a box. This packing method is manual packing. In addition to single copper paper, the cake box can also be made of corrugated paper, which will be more sturdy.

A. With separate Lid and Box:The box and the lid are separated. The main materials are single copper paper and kraft paper. It can be used as a PVC window or not, and the cost is different.

B. One Piece Box: The lid and the box are connected together. The main materials are single copper paper and kraft paper. It can be used as a PVC window or not. In addition, the cake box can also be used to make some card slots for cupcakes, which can be 4 or 6. one and so on.

Cake Stand

5. The last is the cake stand: the main materials are corrugated cardboard and aluminum foil, and finally 250g of paper is used as the bottom paper. Can do 3 or 5 layers.

Related Products

Post time: Mar-26-2022