In an era where sustainability is no longer a choice but a necessity, the packaging industry is undergoing a profound transformation. For bakery businesses, choosing biodegradable packaging isn’t just about meeting environmental regulations—it’s about aligning with consumer values, enhancing brand reputation, and contributing to a greener planet. At Sunshine Bakery Packaging Company, a professional bakery packaging factory, we specialize in turning this vision into reality with our tailored solutions for cake board, cake base board, cake drum, and cake box packaging. As a one-stop provider of customization and procurement services, we understand that every bakery has unique needs, and we’re here to deliver packaging that’s not only eco-friendly but also a true extension of your brand. This guide will walk you through the complete customization process, focusing on logo integration, size precision, and structural innovation—three pillars that define exceptional biodegradable cake box packaging.

.png)

Logo Customization: Making Your Brand Unforgettable

The brand logo is like its "identity card", while the packaging serves as the most prominent "display window" of this identification. Printing the logo on biodegradable cake boxes, cake plates, and cake drums requires balancing aesthetics, durability, and environmental friendliness. This is something we are particularly good at.

Material Compatibility

Not every printing method can be compatible with biodegradable materials, so choosing the right combination of materials and printing techniques is the first step. Specifically: Cake boxes and cake boards made of kraft paper, paired with soy-based non-toxic degradable ink, are the perfect match. Their inherent natural brown base color can make simple or rustic logos stand out even more, which is very suitable for handmade bakery stores. Cake boxes and bases made of sugarcane fibers, with a smooth white surface, are perfectly suited for printing bright full-color logos. We will use water-based ink, which will ensure that the degradability of the material is not affected. Recycled cardboard cake buckets can be processed using embossing or recessing techniques to create tactile logos. Without using too much ink, they can also create a high-end texture.

Placement & Size

When the brand personality varies, the placement of the logo also needs to change accordingly. On the cake box, the logo in the corner has a low-key style, while the one in the center is clearly designed to draw attention. On the cake board, the logo is usually placed in the corner and should be made smaller to avoid blocking the appearance of the cake. The cake bucket itself is large and has a strong presence, so the logo can be placed more prominently, along the edge or in the center, as long as it matches the design of the cake. For large-sized cake boxes like wedding cake boxes, we usually recommend placing the logo vertically on the side, so even when stacked, it can be clearly seen. Additionally, the "moment of opening the box" should also be considered - many brands will hide small logos inside the box cover or at the bottom of the cake board to give customers a little surprise, with ingenious details hidden within.

Durability

Such packaging items as cake boxes, cake plates, cake bases and cake rollers are bound to get damp, be transported, and encounter high temperatures - so the printed patterns on them must be able to withstand all these stresses without any mistakes. Our printing techniques have undergone anti-fouling and durability tests, and these issues have long been taken into consideration. Take UV-cured ink for example (used only in small quantities on specific degradable materials), it can form a protective layer on the surface of the pattern, and it won't be affected even if there is a little moisture. Whether it's a cake box, cake plate or cake roller, the printed patterns on them can remain clean, bright and new from the bakery to the customer's hands.

Size Customization: Perfect Fit for Every Cake

No two cakes are exactly the same, and naturally, the packaging must also have its own unique requirements. If the packaging doesn't fit properly - whether the cake box is too loose or the size of the cake plate is too small - it will cause damage to the cake and waste space as well as increase transportation costs. For cake plates, bases, barrels and boxes, we have specially launched a size customization service, precisely to eliminate all these troublesome issues.

Tailored to Your Cakes

First, let's take a look at the type of your product, so that we can match the packaging appropriately:

For single-serving pastries like cupcakes and mini pies, small cake boxes are needed, with partitions inside to prevent shaking, and the size of the accompanying cake base should also be perfectly matched. Usually, a 4x4x3-inch box is recommended, paired with a 3.5x3.5-inch base, and you can also choose a tray with 2 or 6 compartments.

For standard round or square cakes of 6-12 inches, there should be 1-2 inches of clearance around the box to accommodate frosting and decorations. For example, a 10-inch cake is best paired with a 12x12x6-inch box, along with a 10-inch cake base and a slightly smaller inner base of the box, providing better support.

For layered wedding cakes, special-shaped cakes with unique features, all packaging needs to be custom-sized. We will measure the height, width and weight together with your bakery to ensure the box is properly supported, the roller base is stable, and the base and inner base of the box can fit precisely without wasting space.

Practical Considerations

Stackability: For bakeries that transport multiple cakes, we design cake box sizes that stack securely, reducing the risk of toppling. This often means uniform base dimensions with interlocking lids. Cake drums, with their sturdy construction, are also designed to stack well when not in use.

Storage Efficiency: Our flat-foldable cake boxes (available in all custom sizes) save space in your bakery when not in use. A 12-inch square cake box, for example, folds down to just 1 inch thick. Cakeboards and cakebaseboards can be stacked flat, and cake drums are designed to nest inside one another for efficient storage.

Cost-Effectiveness: By minimizing excess material in cake boxes, cakeboards, cakebaseboards, and cake drums, we reduce waste and lower your costs. A precisely sized cakeboard uses 15-20% less material than a generic “one-size-fits-all” option, and the same principle applies to the other packaging items.

Structure Customization: Function Meets Innovation

The construction of the cake box, along with the styles of the cake plate, base plate and barrel, not only affects the protection effect of the cake, but also influences the customers' intuitive perception of the brand. We have prepared a variety of structural schemes for these packaging items, and each one precisely meets different needs.

Specialized special model

Transport-focused structure: For delivery services, the cake box will be reinforced with corner angles, filled with padding and equipped with safety locks to prevent the cake from shaking. Some will also be equipped with handles made of degradable materials for easy carrying. The cake barrel can be designed with a non-slip surface to ensure the cake is stable during transportation.

Environmental-friendly accessories: Multi-layer cake packaging does not use plastic padding, but uses biodegradable cardboard partitions. The box for layered cakes has adjustable inner supports that can be folded flat when not in use; the edges of the cake plate adopt interlocking design to firmly fix multi-layer cakes.

Seasonal limited edition: Special designs will be released during holidays - such as the heart-shaped cake box and cake plate for Valentine's Day, and window grilles with snowflake patterns on the box surface for winter. These designs can keep the packaging fresh and timely.

Why Biodegradable Cake Packaging Matters

At Sunshine Bakery Packaging Company, we’ve made it our mission to merge sustainability with functionality. Our core products—cake board, cake base board, cake drum, and cake box—are designed to meet the highest standards of both environmental responsibility and performance. Whether you’re a small local bakery or a large chain, our one-stop service ensures that from design to delivery, your packaging needs are met with precision and care. As a dedicated bakery packaging factory, we have the expertise and equipment to produce these essential packaging items with consistent quality.

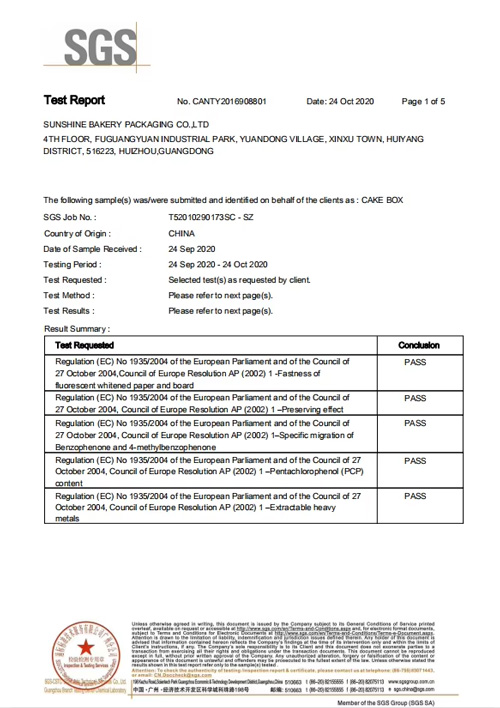

SGS

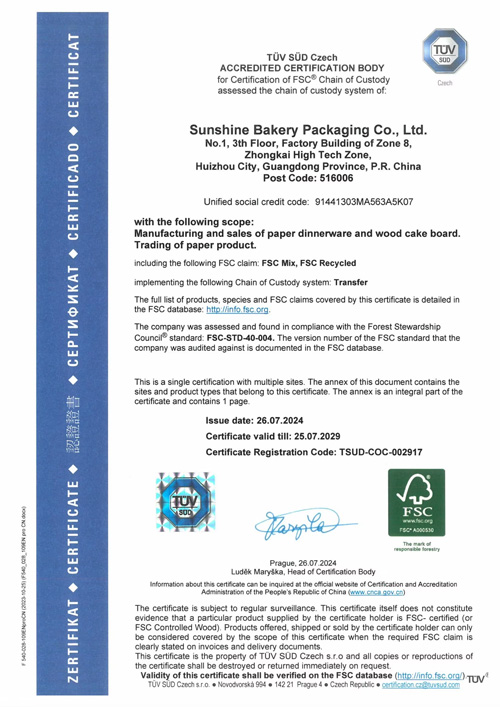

FSC

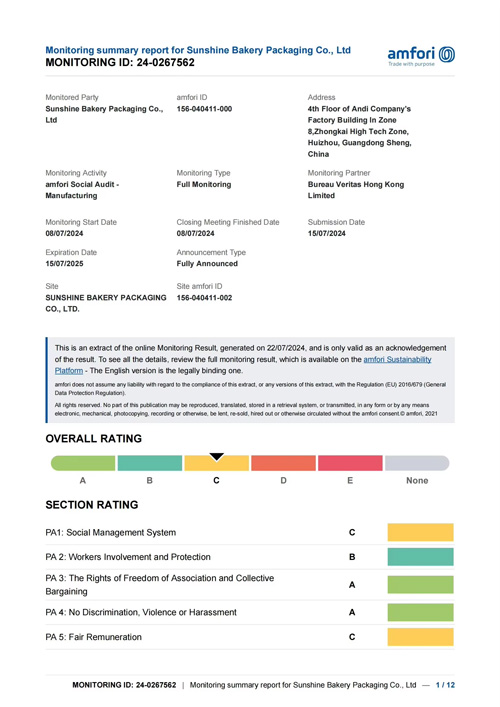

BSCI

Practical Considerations

- Stackability: For bakeries that transport multiple cakes, we design cake box sizes that stack securely, reducing the risk of toppling. This often means uniform base dimensions with interlocking lids. Cake drums, with their sturdy construction, are also designed to stack well when not in use.

- Storage Efficiency: Our flat-foldable cake boxes (available in all custom sizes) save space in your bakery when not in use. A 12-inch square cake box, for example, folds down to just 1 inch thick. Cakeboards and cakebaseboards can be stacked flat, and cake drums are designed to nest inside one another for efficient storage.

- Cost-Effectiveness: By minimizing excess material in cake boxes, cakeboards, cakebaseboards, and cake drums, we reduce waste and lower your costs. A precisely sized cakeboard uses 15-20% less material than a generic “one-size-fits-all” option, and the same principle applies to the other packaging items.

Basic Structures

Foldable Cake Boxes: The most common and cost-effective option, these are easy to assemble and store. They work well for everyday cakes and are available with tuck-in lids or magnetic closures (for a touch of luxury).

Sturdy Cake boards and Cake base boards: Available in round, square, and custom shapes, these are designed to provide a stable platform for cakes. Cake base boards are often slightly thinner than cake boards but still offer reliable support, making them a great choice for lighter cakes.

Durable Cake Drums: These are thicker and more rigid than cake boards, ideal for heavy or tiered cakes. They come in various heights to add a decorative element to the cake presentation, with options for smooth or textured surfaces.

Drawer Cake Boxes: Ideal for high-end bakeries, these slide open smoothly, adding a sense of occasion. They’re often used for gourmet dessert boxes or gift sets, paired with matching cake boards.

Window Cake Boxes: A clear, biodegradable PLA window (made from plant-based materials) lets customers see the cake inside, enticing purchases. We can shape windows into circles, squares, or even custom outlines (e.g., a cupcake shape for cupcake boxes).

Specialized Designs

Transport-Focused Structures: For delivery services, we add reinforced corners, padded inserts, and secure locking mechanisms to cake boxes to prevent shifting. Some clients opt for handles (made from the same biodegradable material) for easy carrying. Cake drums can be designed with non-slip surfaces to keep cakes stable during transport.

Eco-Friendly Add-Ons: Instead of plastic inserts, we use biodegradable paper dividers for multi-cake boxes. For tiered cakes, we design adjustable internal supports in cake boxes that fold flat when not in use, and cakeboards with interlocking edges to connect multiple tiers securely.

Seasonal Variations: During holidays, we create limited-edition structures—think heart-shaped cake boxes and cakeboards for Valentine’s Day or snowflake-patterned windows on cake boxes for winter. These designs keep your packaging fresh and relevant.

Our One-Stop Customization & Procurement Service

As a leading bakery packaging factory, we understand that managing packaging can be overwhelming, which is why we’ve streamlined the process into a seamless experience:

Consultation: Our team starts by listening to your needs—your cake sizes, brand aesthetic, budget, and sustainability goals. We provide samples of various cake boards, cake base boards, cake drums, and cake box materials and structures to help you visualize options.

Design & Prototyping: Our in-house designers create 3D mockups of your custom cake box, along with designs for cake boards, cake base boards, and cake drums, including logo placement and structural details. We then produce physical prototypes for your approval, making revisions until they’re perfect.

Production: Once approved, we handle bulk production with strict quality control. As a bakery packaging factory, we have full control over the manufacturing process, ensuring that every cake board, cake base board, cake drum, and cake box meets our high standards. We source all materials from certified sustainable suppliers, ensuring transparency from start to finish.

Delivery: We coordinate logistics to ensure your packaging items arrive on time, whether you need a small batch for a seasonal promotion or a large order for year-round use.

Why Choose Sunshine Bakery Packaging Company?

Comprehensive Product Range: As a full-service bakery packaging factory, we offer everything from cake boards and cake base boards to cake drums and cake boxes, ensuring consistency in quality and branding across all your packaging needs.

Sustainability Without Compromise: Our materials for all products are 100% biodegradable, compostable, or recyclable, and our processes minimize water and energy use.

Customization Expertise: We don’t just sell packaging items—we create packaging solutions that reflect your brand’s unique identity, whether it’s on a cake box, a cake board, or a cake drum.

Reliability: With years of experience in the bakery industry as a trusted bakery packaging factory, we understand the challenges you face (last-minute orders, tight deadlines) and adapt to meet them.

Value: Our one-stop service reduces costs associated with working with multiple vendors, and our efficient designs save you money on materials and shipping for all your cake packaging needs.

Your cake is a work of art—its packaging should be too. At Sunshine Bakery Packaging Company, we’re committed to providing you with biodegradable cake boxes, cake boards, cake base boards, and cake drums that protect your products, showcase your brand, and honor your commitment to the planet. Let’s create packaging that makes both your cakes and your customers shine. Contact us today to start your customization journey.

Related Products

Post time: Jul-18-2025