In an era where environmental awareness is on the rise, the baking industry is actively embracing the wave of green consumption. SunShine regard the bulk purchase of eco-friendly cake boxes as a crucial step in practicing sustainable development. However, numerous hidden pitfalls in the procurement process often lead companies to achieve minimal results despite significant efforts in pursuing environmental goals. In some cases, poor decision - making can even trap businesses in a dilemma of rising costs and damaged reputations. To strike a balance between environmental protection and business benefits, it is essential to be wary of the following five major procurement mistakes.

1.Misled by Marketing Language and Lacking In - depth Material Verification

Glamorous labels such as "biodegradable" can easily make purchasers lower their guard. A mid - sized bakery chain once bought a large quantity of cake boxes labeled "rapidly biodegradable." In practice, they found that these boxes showed almost no signs of decomposition in ordinary waste disposal environments. Subsequent testing revealed that their degradation required specific industrial composting equipment, which is extremely scarce in urban waste treatment systems. Similarly, packaging made of composite materials harbors hidden risks - the plastic film lining beneath the paper surface makes it difficult for recycling sorting equipment to process, causing a large amount of such packaging to end up in landfills.

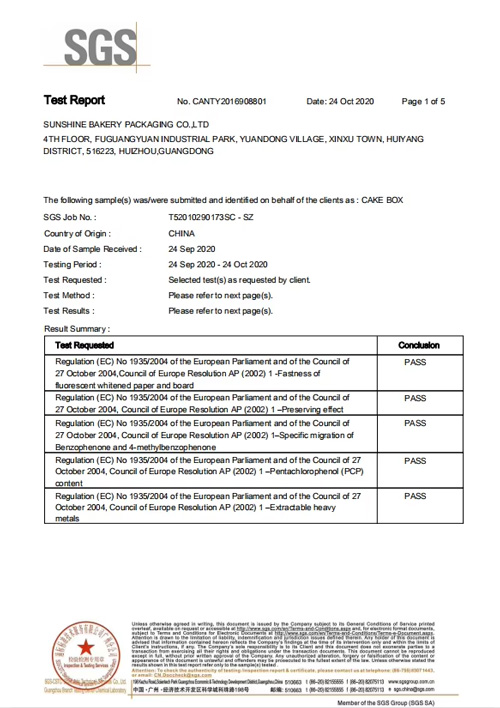

To avoid such risks, a strict material review mechanism should be established. Require suppliers to provide authoritative documents such as SGS test reports. At the same time, pay attention to the source of raw materials. Take bamboo fiber materials as an example; they only require 3 - 4 years for growth, making them more sustainable compared to wood - based raw materials.

.png)

2.Inadequate Size Planning, Causing a Surge in Full - Chain Costs

The size and load - bearing design of cake boxes directly affect the efficiency of the supply chain. A start - up dessert brand, aiming to save on design costs, uniformly purchased standard - sized packaging boxes. However, due to not considering the height of mousse cakes, 30% of the products were deformed by extrusion during transportation. Another enterprise, which chose cardboard boxes with a thickness of only 250gsm, suffered product losses exceeding ten thousand yuan during the peak holiday order season due to the collapse of the packaging boxes.

Precise size management needs to combine sales data with transportation scenarios. Analyze sales records of cakes over the past six months to categorize different specifications such as 6 inch, 8 inch, and multi - tiered cakes. During load - bearing tests, simulate transportation conditions such as stacking pressure and vibration. Select corrugated cardboard with a strength of 350gsm or higher or designs with honeycomb structures. Some companies adopt foldable and adjustable modular packaging boxes, which can be adapted to various sizes, effectively reducing inventory pressure and procurement costs.

3. Over - Decorating Packaging, Deviating from the Original Environmental Protection Aspirations

Packaging design often falls into the trap of "aesthetics above all else." A popular online cake brand used a large amount of gold stamping and PVC transparent windows on its packaging boxes to create a visual impact. Although this increased the product's premium, the recycling rate of such packaging was less than 5%. Industry research shows that decorative accessories such as ribbons and plastic gaskets account for 12% - 18% of the total packaging weight. However, due to the difficulty of separating and recycling them, they have become an environmental burden.

To balance aesthetics and environmental protection, the minimalist design concept can be borrowed. Use water - based inks for screen printing, which can present delicate patterns while ensuring that the printed layer is biodegradable. Replace lamination with processes such as hollow carving and embossing, which not only enhance the texture of the packaging but also avoid plastic pollution. Some brands design their packaging as reusable storage boxes or incorporate plant seeds, allowing consumers to plant them directly after use, thus extending the value of the packaging.

4. Supplier Selection Driven by Low Prices, Concealing Supply Chain Risks

Procurement decisions driven by price often plant hidden dangers. A regional bakery brand, after switching to a low - cost supplier, received complaints for hundreds of orders due to excessive ink odor in the cake boxes. More seriously, some suppliers, in order to reduce costs, illegally purchase wood from unregulated forest farms. Once exposed, the purchasing enterprise will face the crisis of a collapsed brand image.

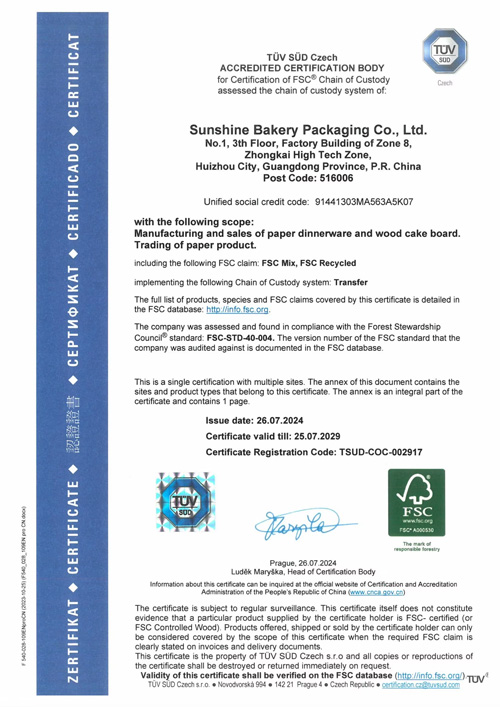

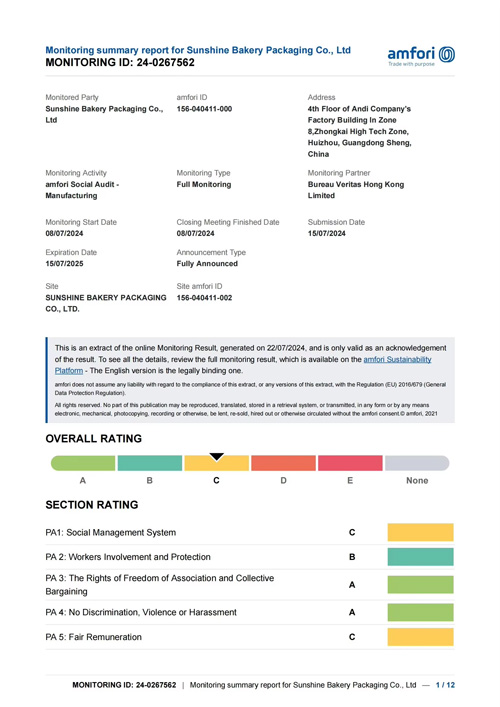

Establishing a reliable supplier evaluation system is of great importance. In addition to reviewing qualification certificates, suppliers can be required to provide production workshop videos, raw material purchase orders, and other traceability materials. Give priority to companies certified by ISO 14001 environmental management system or cooperate with local suppliers. This can not only shorten the transportation radius and reduce carbon emissions but also facilitate on - site inspections. A leading bakery enterprise has implemented a "green supplier scoring system," which evaluates suppliers from dimensions such as environmental protection investment and on - time delivery rate, effectively screening out long - term and stable partners.

SGS

FSC

BSCI

5.Neglecting Storage and Transportation, Losing Control of Packaging Losses

Storage and transportation management is often overlooked by purchasers. A cold - chain distribution enterprise, due to not considering moisture - proof requirements, saw 20% of its paper packaging boxes become soft due to moisture during the rainy season, doubling the product damage rate. Some enterprises, due to the unreasonable stacking design of their packaging boxes, wasted 30% of their storage space, increasing rental costs unnecessarily.

Optimizing storage and transportation solutions should start from the source of packaging design. Select paperboard with waterproof bio - coatings or add moisture - proof layers to the box body. Adopt two - piece box structures that can be nested for stacking, which can increase the storage space utilization rate by 40% compared to ordinary folding boxes.

Conclusion

The bulk purchase of eco - friendly cake boxes is by no means a simple transaction. It is a systematic project involving the entire supply chain. Only by avoiding the above - mentioned misunderstandings and formulating procurement strategies with a scientific and rigorous attitude can businesses achieve a dual improvement in environmental commitments and commercial values, and gain a competitive edge in the wave of the green economy.

Related Products

Post time: Jun-25-2025